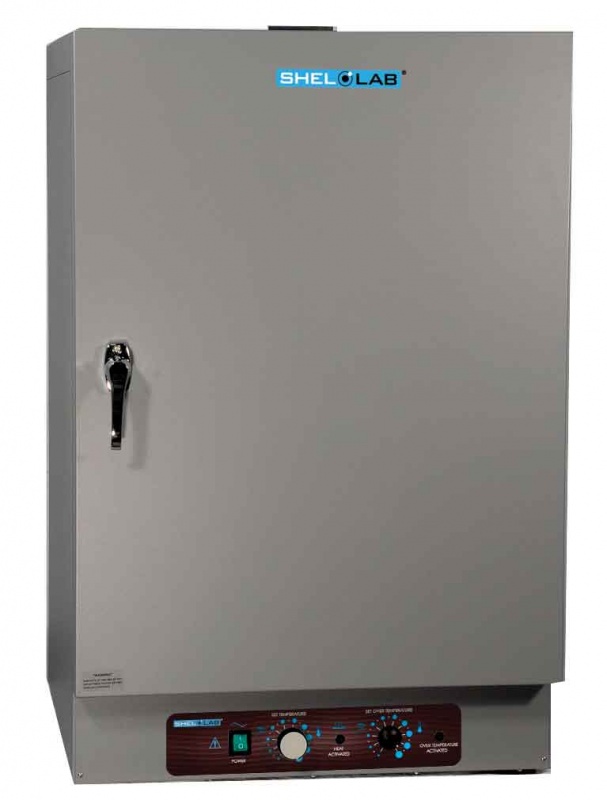

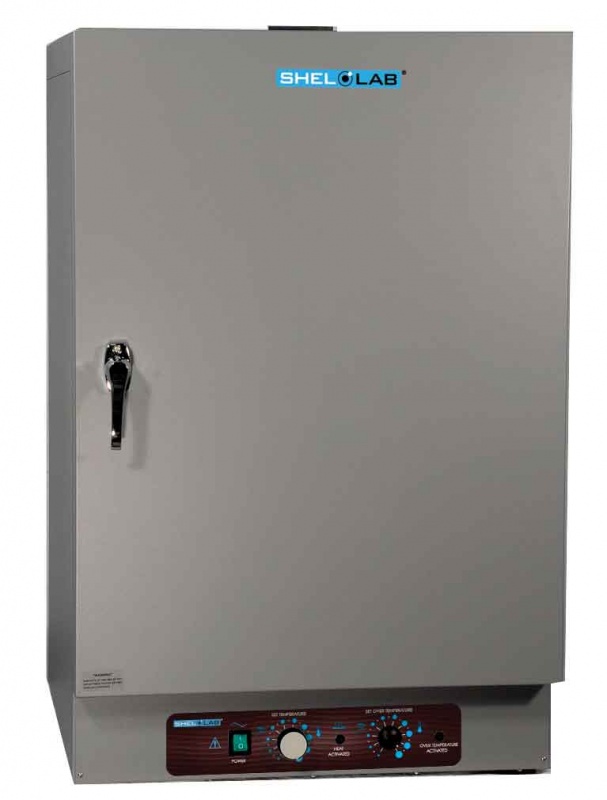

Oven applications are very diverse, but it is possible to break down their uses into three main categories: Drying, Baking and Curing.

Drying Ovens- These ovens remove moisture from the chamber as quickly as possible in order to dry samples. The more air that moves over the samples and the more air that is evacuated from the chamber, the faster the samples will dry. This is why SHEL LAB ovens come with adjustable intake and exhaust ports for quick evacuation of chamber air when necessary.

Baking Ovens- These ovens heat samples over a period of time without drying them out. This is best accomplished by keeping the exhaust port closed. The other key to this process is minimizing heat loss because the heated air is holding moisture. For this reason, SHEL LAB ovens use a unique wrap around insulation method that leaves no seams or gaps for air to escape.

Curing Ovens- These ovens slowly heat materials to alter their chemical or physical properties. In other words, this method is aimed at baking samples while slowly drying them as well. Again, the amount of air allowed to evacuate the chamber plays a key role in the success of this process. The SHEL LAB family of laboratory ovens range in size from 2 cu.ft. to 40 cu.ft. with many different features available.

Applications include: Batch Testing, Aging Tests, Sterilizing, Electronic Burn-in, Conditioning, Preheating Process, Components Processing, Stability Testing, Glassware Drying, Asphalt Testing